In order to encourage enterprises in the field of building sanitary ceramics to strengthen scientific and technological innovation, cultivate and strengthen the scientific and technological strength of enterprises, and implement the concept that scientific and technological innovation drives high-quality development of enterprises, China Building Sanitary Ceramics Association has organized 7 times of application and evaluation of "China Building Sanitary Ceramics Industry Scientific and technological Innovation Award" since 2015.

At present, the award evaluation of the Association in 2021 has been completed, and the results have been publicized. A total of 28 technical achievements have been awarded, including 3 first prizes, 16 second prizes and 9 third prizes. The official account and website of the association will provide special reports for the prize-winning achievements. This article will introduce the first prize project of Scientific and technological progress awarded by Guangdong Nader New Materials Co., LTD. "Development and application of remote digital ceramic (rock slab) Edging and polishing Anti-fouling Intelligent Manufacturing System and Process Technology".

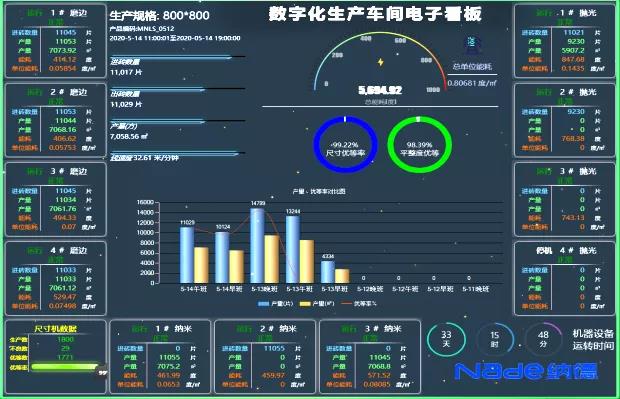

This item is on guangdong's new material co., LTD for many years deep processing of ceramic production technology, king kong products with abrasive, under the premise of nano functional materials such as technology, the integrated nader brick of pottery and porcelain (board) the latest intelligent polishing antifouling advanced technology on the basis of the whole line equipment, increased the fiber BoYan plate processing technology of special requirements of consideration, In order to realize the ceramic tile (board) deep processing of networked intelligent production for the purpose of setting up. Nader intelligent ceramic tile (board) edge grinding and polishing antifouling processing system, not only meets the ceramic tile (board) deep processing technology requirements, but also has the function of remote digital intelligent control.

Guangdong Nader New Materials Co., Ltd. has set up three scientific research teams with clear professional division of labor and tacit cooperation, which are unique in intelligent manufacturing equipment technology, diamond products abrasive material technology and nano functional material technology, and are in the leading position in the industry. In addition, there is a long-term adhere to the ceramic deep processing OEM team in the production line, for the enterprise's scientific research and development from the line of mature technology, and undertake the task of process test!

Nader has its own enterprise technology and engineering center, provincial engineering center and municipal technology center and other scientific research institutions. While adhering to the long-term cultivation of independent research and development ability of enterprises, Nader has also established long-term industry-university-research cooperation alliance with jingdezhen Ceramic University and other scientific research institutions. After more than ten years of exploration, Nader has obtained a number of patents and software copyright and other intellectual property rights in the field of ceramic deep processing.

1) On the basis of integrating the latest intelligent whole line equipment technology, through software development and system integration design, the intelligent ceramic tile (board) edge grinding and polishing anti-fouling processing system is developed, which realizes two-way communication with ERP system and remote digital control of the whole line networking equipment;

2) developed data acquisition and video monitoring subsystem, through data collection, sharing, processing, output, remote monitoring, analysis, and the use of the Internet of things, such as mobile network technology, set up a brick of pottery and porcelain (plate) deep processing of one-stop industrial data collection, analysis of comprehensive monitoring management system, realized the brick of pottery and porcelain (plate) processing link flexible customization production;

3) Through the establishment of network system, the interconnection between machine and machine, machine and system is realized, as well as the self-recognition, self-adaptation and self-optimization function of ceramic tile (plate) deep processing link;

4) Developed anti-jitter structure grinding head and exclusive grinding block formula and structure, which can effectively control the damage rate and realize energy-saving and efficient production while ensuring the deep processing requirements of thin rock plate;

5) It deepens the processing technology of nano-functional materials on the surface of ceramic tiles (plates), and improves the performance of anti-skid, anti-fouling and anti-bacteria of ceramic tiles (plates).

This project is aimed at the needs of ceramic tile (board) and artificial stone plate enterprises to transform and upgrade to the direction of intelligent manufacturing for research and development, realizing the networked intelligent manufacturing of edge polishing anti-fouling processing, and effectively exploring the construction of "building ceramic intelligent factory".

Products dominated the project began to be developed in March 2019, in January 2020 and March 2020, respectively, the Mona Lisa new material co., LTD. To begin industrial operation, gold ceramics co., LTD., has reliable production system running normally, each performance index of all to the design requirements, users satisfied with the project's product usage.

The project in order to realize the intelligent architectural pottery making as the goal, to reduce operating personnel quantity, reduce the work load of operating personnel, reduce the operator labor skill, for the purpose of the main innovative technology has been successfully applied to many well-known brand ceramic plates of the polishing antifouling intelligent production, market and application prospect.

1) Economic benefits

In 2021, it is expected that 10 sets of products of this project will be sold in the whole line, and the annual sales will be over 100 million yuan, and the profits and taxes will be over 10 million yuan.

2) Social benefits

First, boost the building ceramic industry to the direction of intelligent manufacturing transformation and upgrading;

Second, for the building materials machinery and equipment industry to advanced equipment manufacturing industry transformation and upgrading, play a demonstration role;

Third, it is in line with national industrial policies: "Made in China 2025" clearly states that by 2025, China's manufacturing industry will enter the second phalanx in the world and "step into the ranks of manufacturing powers".

Fourth, the improvement of the degree of intelligence reduces the number of operators, reduces the labor intensity of operators, reduces the labor skill requirements of operators, and ensures the stability of the industrial team.

上一篇:没有了!

下一篇:没有了!